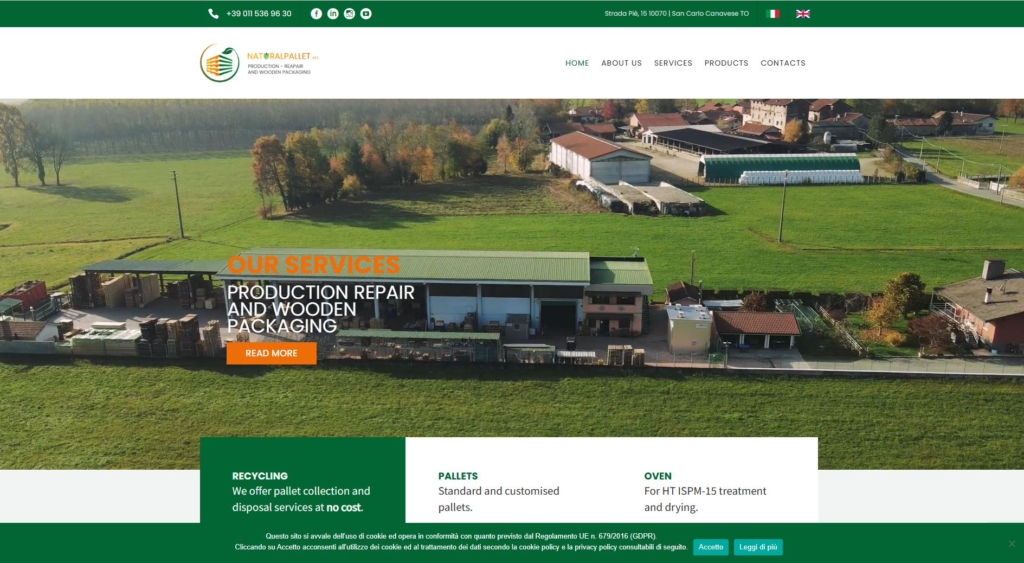

Natural Pallets in Italie koopt als eerste Italiaans palletbedrijf een sorteer-reparatielijn van Pallet Sorting Systems

Natural Pallets S.r.l. – Pallet repair line with six workstations and overhead waste conveyor

Natural Pallets S.r.l., based in Italy, has invested in a pallet repair line from Pallet Sorting Systems (PSS).

With this installation, the company takes a significant step towards automation and process optimisation in the Italian pallet industry.

The line is designed for six pallet repair workstations, allowing operators to work efficiently within a clean, ergonomic and organised environment.

Machine description

The pallet repair line features side infeed where pallets are delivered by forklift onto non-driven roller conveyors.

Damaged pallets are brought to the repair stations, where repairers receive them at an ergonomic working height.

Once repaired, pallets can be sorted into five automatic stackers, each assigned to a different pallet type or quality.

Above the repair line, an overhead waste conveyor removes wood, paper and plastic to dedicated collection containers.

This design keeps the work area clean and safe, reducing manual waste handling and improving productivity.

Benefits for operators

The line is built with focus on ergonomics, safety and efficiency:

-

Ergonomic working height at all repair stations – no bending or heavy lifting.

-

Clean workspace thanks to the overhead waste conveyor.

-

Easy side infeed via roller conveyors – pallets are always within reach.

-

Less physical strain and reduced walking distances.

-

Organised workflow, each repairer has their own infeed and outfeed section.

Benefits for the company

The PSS pallet repair line provides Natural Pallets with measurable business benefits:

-

Six simultaneous repair stations for high daily capacity.

-

Five automatic stackers for sorting repaired pallets by type or quality.

-

Efficient waste management via overhead conveyor with separate collection of wood, paper and plastic.

-

Reduced forklift traffic due to side infeed handling.

-

Modular and expandable design – additional stackers or stations can be added later.

-

Improved safety and workflow organisation.

-

Lower operational costs through shorter handling times and efficient material flow.

Efficiency and monitoring

Like all PSS systems, the repair line can be connected to PSS SCADA for data reporting, including:

-

number of repaired pallets per operator,

-

total working hours and cycle times,

-

performance data per stacker or pallet quality.

All information can be monitored in real time via the PSS App, giving management full insight into production and performance.

Results

With this investment, Natural Pallets S.r.l. operates a modern, ergonomic and efficient pallet repair process.

The line combines clean working conditions, reduced handling, and automated waste removal – supporting both productivity and safety on the shop floor.

Pallet Sorting Systems proudly supports Natural Pallets in modernising their pallet operations and driving automation within the Italian market.

Pallet Sorting Systems – Modular. Reliable. Efficient.