Kloek Pallets Kampen – Combined pallet sorting and repair line with double MultiSorter from PSS

Kloek Pallets – Combined pallet sorting and repair line with double MultiSorter from Pallet Sorting Systems

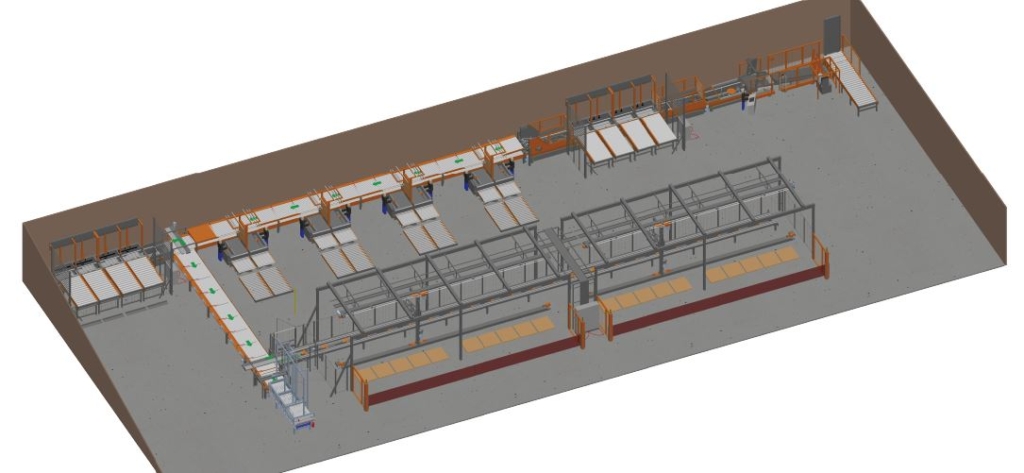

Kloek Pallets, based in Kampen (Netherlands), has expanded its pallet handling capacity with a combined pallet sorting and repair line, designed and built by Pallet Sorting Systems (PSS).

This is the fourth PSS installation for Kloek Pallets, highlighting their ongoing commitment to automation and digitalisation of pallet processing.

The new setup connects sorting and repair into one integrated process – designed for maximum efficiency at every stage and ready for future AI integration.

Machine description

At the infeed section, four inline stackers with discharge conveyors automatically remove the most common approved pallets from the process.

This allows operators to separately sort pallets that are needed on demand without interrupting the main workflow.

Behind the sorting area, there are eight in-line pallet repair stations.

Each workstation receives only defective pallets via an overhead conveyor, ensuring that repairers focus solely on damaged pallets.

A side infeed supplements the supply during lower repair volumes, keeping all repairers continuously productive.

At the rear of the line, four additional inline stackers handle fast-moving pallet types such as Euro pallets, while the double MultiSorter manages less common or irregular pallet sizes.

Double MultiSorter with 20 positions

The installation includes a double MultiSorter for handling non-standard pallets, such as CP pallets, block pallets or custom-built designs.

With 20 stacking positions, the MultiSorter recognises, picks and stacks various pallet sizes automatically and precisely.

Two additional stackers are dedicated to block pallets – one of them features an automatic paint-spray unit that colour-marks the side beams for quick visual identification in downstream logistics.

Benefits for operators

The line has been designed with strong focus on ergonomics, flow and safety:

-

Sorter:

-

Operates from the main station and can process up to 500 pallets per hour.

-

No manual stacking – all pallets are handled by the automated stackers and MultiSorter.

-

Maintains full overview of both the approved and defective pallet flows.

-

-

Repair operators (8 workstations):

-

Receive only defective pallets via the overhead conveyor, eliminating manual lifting and transport.

-

Ergonomic benefit: fixed working height, minimal physical strain.

-

Continuous infeed via overhead and side conveyors ensures balanced workload.

-

Fewer forklift movements and a safer, cleaner workspace.

-

Increased repair output through uninterrupted pallet flow.

-

Benefits for the company

For Kloek Pallets, the new line delivers measurable operational advantages:

-

Integrated sorting and repair process with seamless material flow.

-

Four automatic stackers at the front and four at the rear for continuous output.

-

Double MultiSorter with 20 positions for diverse pallet formats.

-

Dedicated handling for block pallets with automatic colour-marking system.

-

Up to 500 pallets per hour sorting capacity.

-

50% fewer forklift movements, reducing internal transport costs.

-

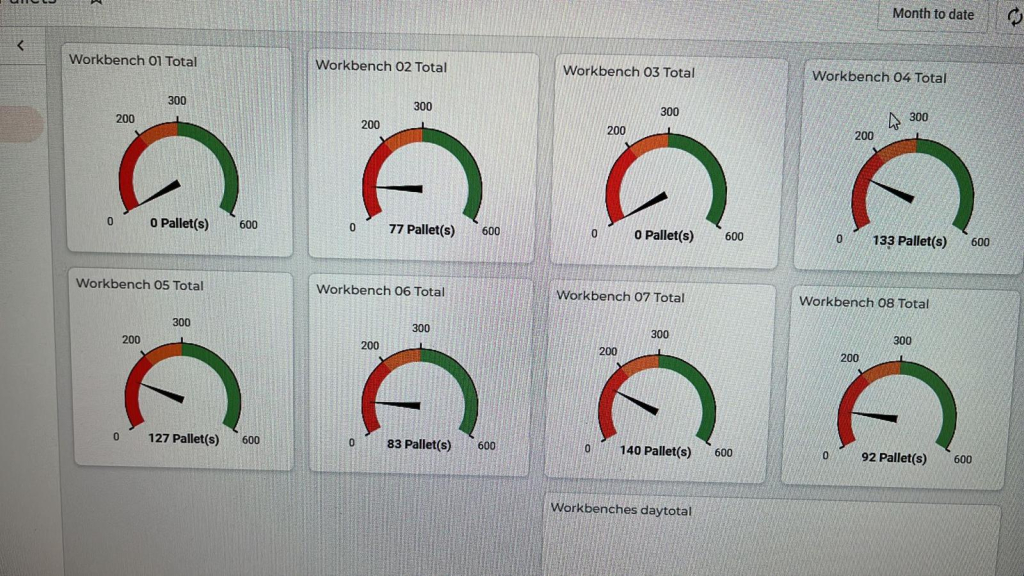

SCADA monitoring with live production data and employee performance reports.

-

PSS Live App for remote access and real-time performance tracking.

-

Ai4Pallets-ready – prepared for AI-based pallet recognition and quality inspection.

Efficiency and monitoring

The entire system runs on the PSS SCADA platform, providing clear visualisation of:

-

total production throughput,

-

output per operator,

-

repair and sorting statistics,

-

system uptime and efficiency metrics.

The PSS Live App allows managers to monitor performance remotely, supporting continuous optimisation and data-driven decision-making.

Ready for Ai4Pallets

The installation is fully prepared for Ai4Pallets integration.

Future upgrades can include:

-

automatic pallet recognition by type and customer recipe,

-

visual quality control using camera technology,

-

intelligent decision logic for repair or reuse.

This modular setup ensures scalability and digital growth for Kloek Pallets.

Results

With this new installation, Kloek Pallets achieves:

-

Higher throughput and production stability.

-

Ergonomic advantage for eight repair operators via automatic pallet delivery.

-

Consistent sorting quality using stackers and double MultiSorter.

-

Real-time monitoring via SCADA and the PSS Live App.

-

Future-ready AI integration for next-generation pallet handling.

The collaboration between Kloek Pallets and PSS demonstrates how modular automation leads to greater efficiency, reduced forklift traffic and complete process control.

Pallet Sorting Systems – Modular. Reliable. Efficient.