Foresco Sort & Repair Veghel BV – Efficient pallet sorting and repair with Pallet Sorting Systems

Foresco Sort & Repair Veghel BV – Efficient pallet sorting and repair with Pallet Sorting Systems

Foresco Sort & Repair Veghel BV has modernised its pallet handling process with a pallet sorting line from Pallet Sorting Systems (PSS). This installation replaces an older system and aligns perfectly with the daily workflow in Veghel. Originally designed for vd Anker Pallets, the line was smoothly integrated into Foresco’s operations and adapted to their specific needs.

Machine description

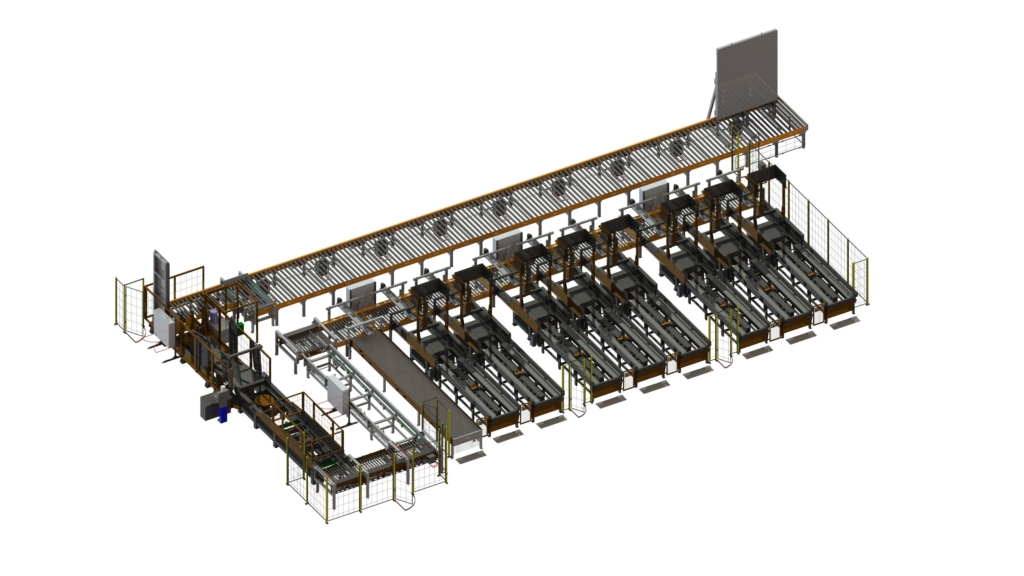

The sorting line features a dual infeed section, a central sorting workstation, and outline stackers with buffering capacity.

This configuration allows Foresco to buffer a full truckload of pallets, ensuring continuous operation without downtime.

The system can sort up to eight pallet types, including Euro, Chep, LPR, IPP and Industrial pallets, and automatically switches between pallet formats without manual adjustment.

Damaged pallets are automatically interlocked and transferred to the repair section via the upper conveyor belt.

Benefits for operators

-

Ergonomic workstation – operators only perform visual inspections for labels or loose parts; heavy lifting and stacking are fully automated.

-

Continuous workflow – the dual infeed prevents waiting times and ensures steady throughput.

-

Safety and comfort – fewer physical movements and an organised workspace improve safety and working comfort.

Benefits for the company

-

Up to 550 pallets per hour with a cycle time of only 6 seconds per pallet.

-

50% fewer forklift movements, reducing handling costs and traffic on the floor.

-

Higher throughput and lower operational costs through continuous flow and automated handling.

-

Flexible processing of multiple pallet types without mechanical adjustments.

-

Reliable service and maintenance supported by PSS’s after-sales and spare-part availability.

-

Sustainable operation, enabling the reuse of pallets and reducing CO₂ emissions.

Efficiency and monitoring

The sorting line is equipped with PSS SCADA reporting and CSV data output, providing insights into production times, operator performance and total throughput.

All data is accessible via the PSS App, allowing management to monitor performance remotely and optimise daily operations.

Results

With this system, Foresco Sort & Repair Veghel BV achieves:

-

Faster and more consistent pallet handling.

-

Lower internal transport and handling costs.

-

Higher productivity per employee.

-

Improved safety and ergonomic working conditions.

This investment prepares Foresco for a sustainable and efficient pallet management future.