Pallet Repair Line

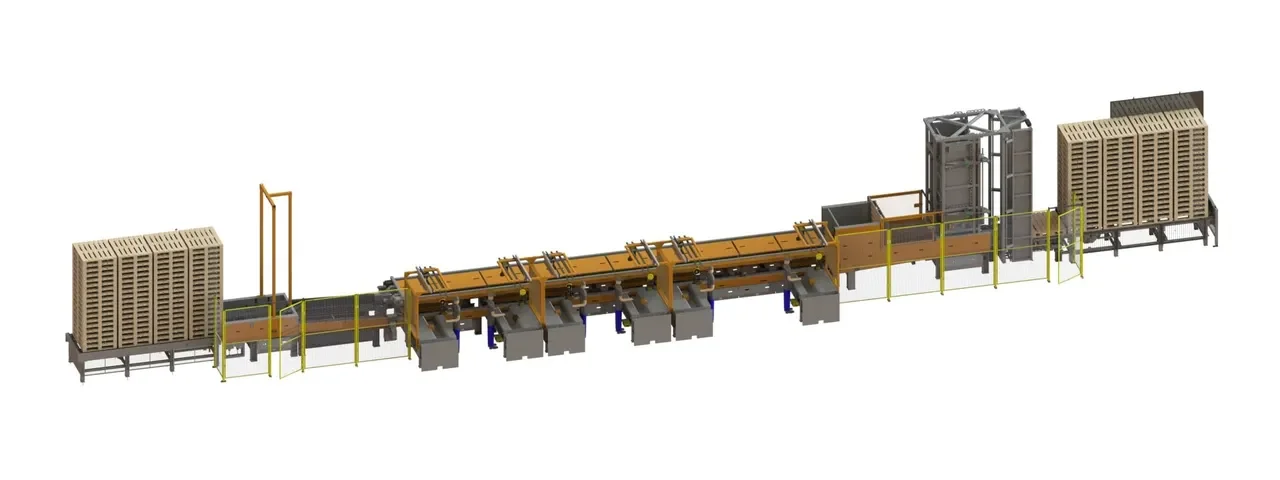

Pallet Repair Line for Efficient Wooden Pallet Repair, placed at Rotom NL.

Pallet Sorting Systems (PSS) develops pallet repair lines that support businesses in pallet repair and refurbishment of wooden pallets. The system focuses on three essential goals: higher output at lower operational cost, improved workplace safety and ergonomically optimised working conditions for repair operators.

In a stand-alone pallet repair line, operators receive pallets via a side-feed roller conveyor with lift table. This removes the need for heavy lifting and long walking distances. Pallets are repaired at work height and automatically transferred to the stacking section afterwards. Forklift drivers work from one defined position, significantly reducing forklift movements and internal transport costs.

All repair data — output per workstation, total repaired pallets and quality details — is automatically documented in a daily CSV report. This makes planning, cost control and pallet management more efficient.

Key customer benefits:

- Higher output through a consistent, predictable process;

- Reduced forklift traffic and lower transport costs;

- Safe workspace with clear walking routes;

- Ergonomic workstations without lifting;

- Full CSV data recording for planning and control.

Pallet Repair and Sorting in One Continuous Workflow

When the pallet repair line is integrated into a PSS pallet sorting line, a highly efficient and clearly structured process is created. The sorting line separates good pallets from repairable pallets. As a result, the repair operator receives only pallets that actually require refurbishment. This increases repair performance by up to 35% and ensures a calm, organised workflow.

The electrically adjustable width (1000 to 1350 mm) allows repair of a wide variety of pallet types. This includes Euro pallets, one-way pallets, block pallets, GMA pallets, 1200×1200 pallets and CP3, CP4, CP5, CP7, CP8 and CP9 pallets. Repaired pallets are automatically stacked according to type and quality.

CSV logs include both sorting and repair data — ideal for companies requiring a transparent and data-driven pallet repair service.

Operational advantages:

-

realistically up to 35% more repaired pallets per shift

-

50% fewer forklift movements and a safer working environment

-

one integrated data stream for sorting and repair;

-

continuous documentation of pallet repair and sorting

-

suitable for all standard and non-standard pallet types

The repairing system in practice

Modular Pallet Refurbishment System With Sorting and Dismantling

The PSS pallet repair line is part of a modular system that can be expanded with AI4Pallets, the MultiSorter and the Robotic Pallet Saw System for automated dismantling of pallets that cannot be repaired economically.

AI4Pallets

AI4Pallets automatically identifies pallet type, dimensions and deck structure. This enables faster and more consistent sorting of pallets and ensures that repairable pallets reach the repair station without unnecessary handling. It also makes pallet repair and sorting independent of operator experience or language skills.

MultiSorter

After repair, the MultiSorter automatically sorts and stacks pallets, supporting a safe and fully automated material flow.

Robotic Pallet Saw System

Pallets that cannot be repaired profitably are forwarded to the Robotic Pallet Saw System via the sorting line and AI4Pallets. Here they are dismantled fully automatically — without any manual intervention. Reusable boards and blocks re-enter the repair process or are recycled.

Daily CSV reports combine data from repair, sorting and dismantling, supporting companies in optimising their pallet management repair service.

Pallet Sorting Systems – Modular. Reliable. Efficient.