KAT EHF – chooses Robotic Pallet Saw System van Pallet Sorting Systems

KAT EHF – Robotic Pallet Saw System by Pallet Sorting Systems

KAT EHF, based in Iceland, has chosen the Robotic Pallet Saw System from Pallet Sorting Systems (PSS).

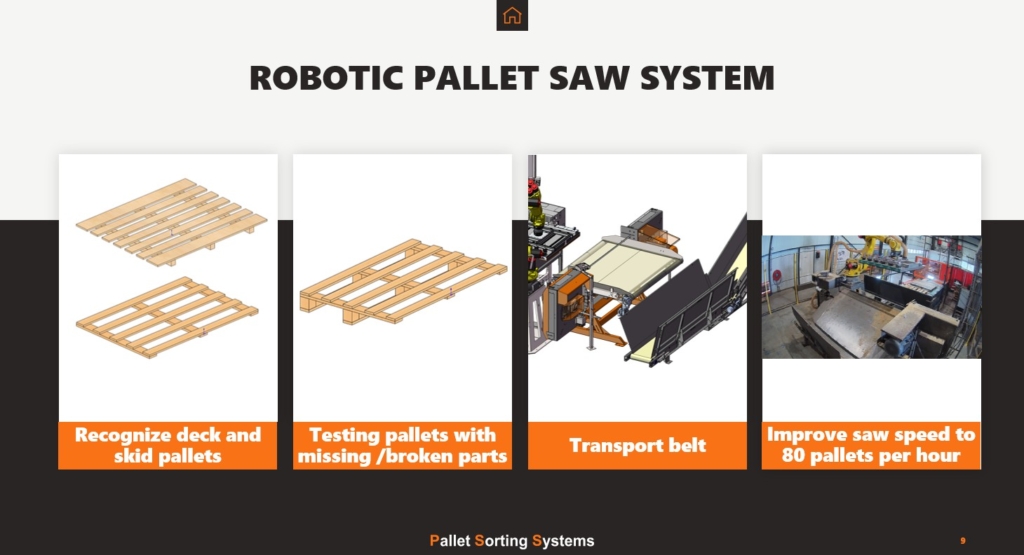

Driven by AI4Pallets, the system cuts and dismantles pallets fully automatically — in random order and across a wide range of pallet types and dimensions — with no manual intervention.

This investment marks a major step toward automated, safe and sustainable pallet dismantling.

1. Why KAT EHF chose PSS

Before making its decision, KAT EHF conducted detailed market research and evaluated multiple saw-system suppliers.

During a live demonstration at Pallet Sorting Systems, the company was strongly impressed by how the system processed

different pallet types, dimensions and deck structures automatically in random play without any operator involvement.

Other systems proved less flexible or required manual adjustments when switching between sizes.

The random-play functionality of the PSS system — combined with AI4Pallets recognition and robot-based handling —

was the decisive factor for both KAT EHF and The Pallet Company in choosing PSS as their automation partner.

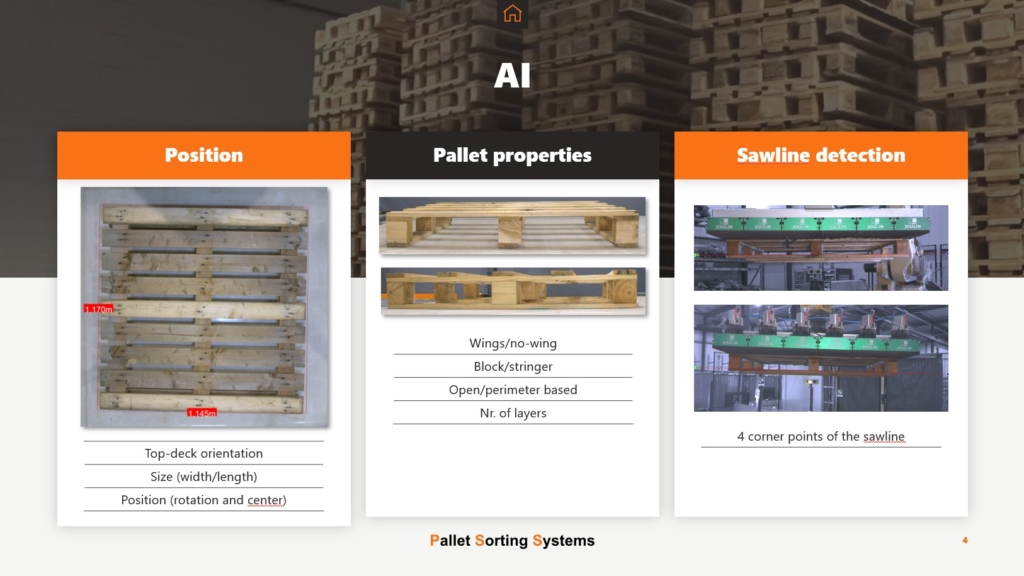

2. Precision cutting with AI4Pallets

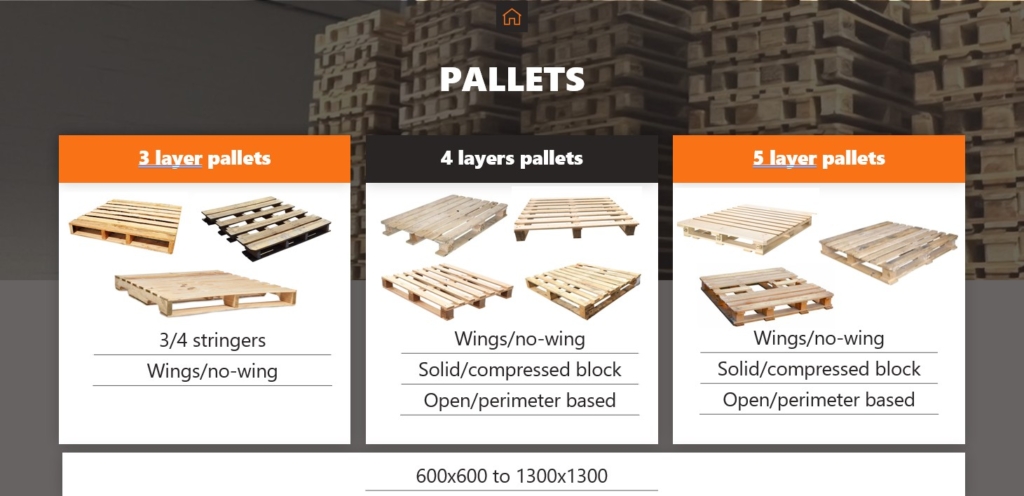

The Robotic Pallet Saw System is equipped with AI4Pallets and several 2D and 3D cameras that automatically identify

the pallet type, size and deck configuration.

The software dynamically adjusts the cutting program in real time, allowing pallets with different layouts — such as Euro, block, GMA or CP pallets —

to be cut consecutively without any need for operator adjustments.

The system automatically selects the correct cutting program (2-, 3-, 4- or 5-layer) and determines the cutting height, length and direction.

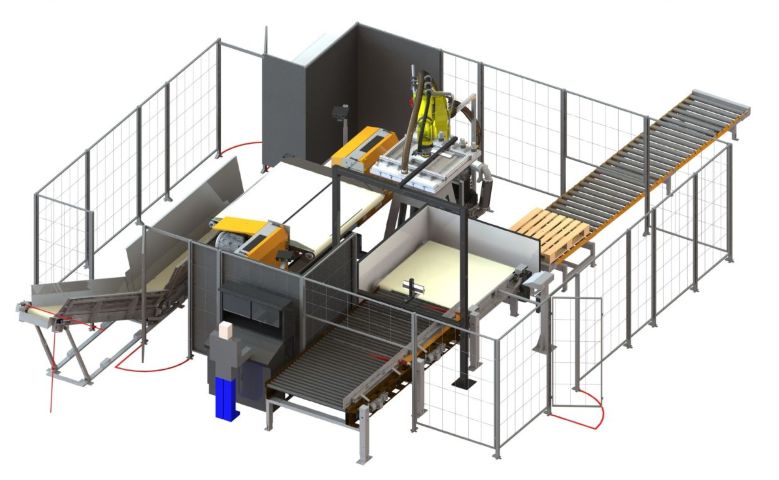

3. Efficiency through robotics

A Fanuc industrial robot equipped with a Joulin vacuum gripper handles all pallet movements.

The robot automatically picks up each pallet, positions it in the saw and removes the dismantled parts.

This ensures an efficient and safe cutting process without human contact.

Key benefits for KAT EHF:

-

Higher production capacity with fewer operators.

-

Lower operating costs through material reuse.

-

Safe dismantling process without manual handling.

-

Reduced downtime and less dependency on operator skill.

4. Operator advantages

The Robotic Pallet Saw System is designed with a strong focus on safety, ergonomics and simplicity.

Operators no longer need to lift or hold pallets manually; the infeed, recognition and cutting cycle are fully automated.

This reduces physical strain, increases workplace safety and ensures a predictable, clean workflow.

Through the integrated PSS SCADA system, operators and managers have real-time insight into:

-

number of pallets processed,

-

cutting cycle times,

-

maintenance status and performance data.

5. Results and business benefits

With the Robotic Pallet Saw System, KAT EHF now operates a solution that:

-

Cuts and dismantles pallets fully automatically without manual handling.

-

Works inline with the sorting line, ensuring a continuous material flow.

-

Reduces labour costs through automated processes.

-

Produces high-quality reusable components for repair or recycling.

6. Future-ready investment

With this investment, KAT EHF demonstrates its commitment to automation and sustainable production.

The Robotic Pallet Saw System enables efficient dismantling and reuse of pallet components,

extending material life cycles and reinforcing circular practices within the pallet industry.

Pallet Sorting Systems – Modular. Reliable. Efficient.