Jassboard invests in an efficient pallet sorting and repair line from PSS

Jassboard – Efficient pallet sorting and repair with adjustable PSS line

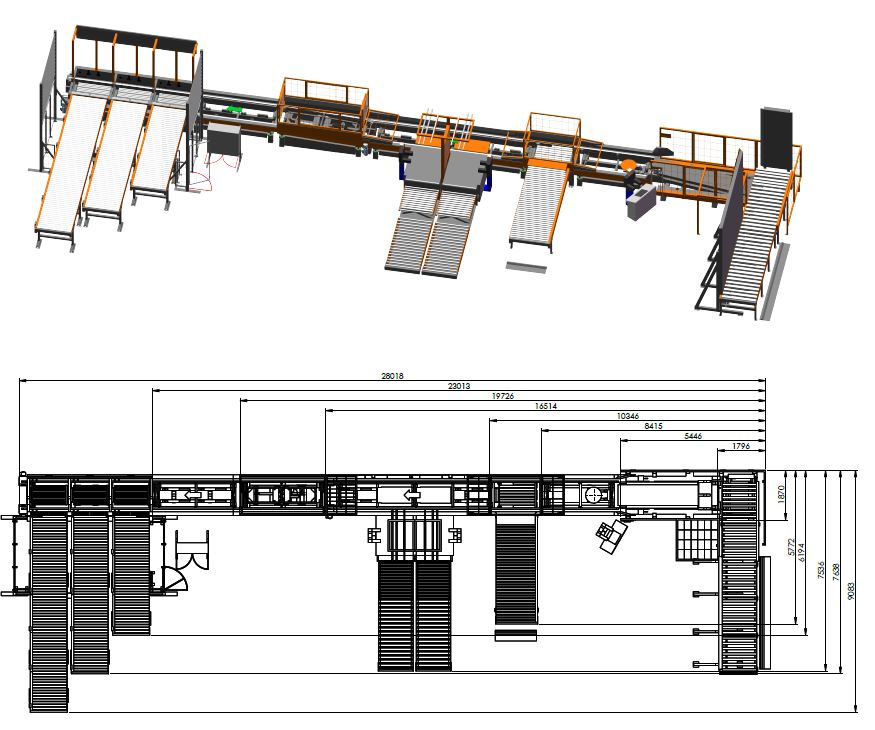

The Polish cardboard manufacturer Jassboard has invested in an adjustable pallet sorting and repair line from Pallet Sorting Systems (PSS) to optimize its internal pallet logistics.

The system combines automatic pallet sorting with integrated repair functions, streamlining the entire process and creating a safer, more efficient workflow.

With this setup, Jassboard operates a single, fully automated line that reduces manual handling, forklift traffic, and downtime while maintaining a constant pallet flow.

One system for multiple pallet formats

The adjustable line can handle both standard and non-standard pallet sizes.

Its width can be continuously adjusted between 100 and 135 cm, allowing it to automatically process Euro pallets as well as CP3, CP4, CP5, CP7, CP8 and CP9 pallets.

This flexible configuration eliminates manual changeovers and ensures consistent and efficient pallet sorting.

Benefits for operators and repair workers

The line is designed with ergonomics, safety and usability in mind:

-

Pallets are delivered at working height, eliminating lifting and bending.

-

Operators work at fixed, safe workstations without nearby forklift traffic.

-

The side feeder delivers only damaged pallets for repair, improving focus and workflow.

-

Overhead waste conveyors remove broken wood pieces, keeping the area clean and organized.

This ergonomic setup increases operator comfort, safety and daily repair output.

Benefits for Jassboard

The PSS system provides Jassboard with measurable business improvements:

-

350–550 pallets per hour processing speed with just one operator.

-

Up to 50% fewer forklift movements thanks to automatic infeed and outfeed.

-

Integrated sorting and repair reduce labour needs.

-

50–60% of pallets reused immediately after light repair.

-

Lower transport and repair costs through local processing.

-

Real-time SCADA data and daily CSV reports via the PSS App.

-

Improved safety and reduced external dependency.

Fast repair without interruption

The line includes four repair stations along the main conveyor.

Defective pallets are automatically fed to these workstations, while good pallets are stacked directly.

Repaired pallets re-enter the line automatically, saving time and reducing forklift movements.

Real-time control with PSS Scada and the PSS App

The integrated PSS Scada system provides full visibility of production performance:

-

total pallets sorted and repaired,

-

individual output per workstation,

-

downtime and cycle data,

-

overall daily performance.

All data is automatically exported to daily CSV reports and can be viewed in real time through the PSS App, allowing managers to monitor and adjust operations anytime.

Sustainable and independent operation

By sorting and repairing pallets locally, Jassboard reduces transport costs and CO₂ emissions.

The closed pallet loop minimizes waste and dependency on external repair suppliers, contributing to both sustainability and operational resilience.

Results

The adjustable pallet sorting and repair line from PSS enables Jassboard to:

-

Process up to 450 pallets per hour,

-

Operate with less staff and 50% fewer forklift movements,

-

Ensure ergonomic, safe workstations,

-

Gain real-time insight through SCADA monitoring,

-

And reduce CO₂ emissions through local repair.

Pallet Sorting Systems – Modular. Reliable. Efficient.